Our Features

Our Features

>> View Our Process Technology

>> View Our Process Technology

Advantages / Disadvantages

1. High efficiency material utilization (high yield)

2. Higher speed, more efficient production

3. Improved product strength by work hardening

4. Cost reductions through customized manufacturing processes

- Forming dies need to be made (initial cost and lead time)

- Time required to set up and adjust production equipment for a particular part, so not well suited to small volume production runs (best for mass production)

- By nature, cold forming leaves radii on most corners and precision is not as high as with machining.

Cold Forming vs Machining

| Machining | Cold Forming | |

|---|---|---|

| Dies | Not Neccesary |

Neccesary |

| Material Yield | ✘ | ✔✔ |

| Processing Speed | ✘ | ✔✔ |

| Strength | ✔ | ✔✔ |

| Process Precision | ✔✔ | ✔ |

| Large Scale Production | ✔✔ | ✔ |

| Small Scale Production | ✘ | ✔✔ |

| Prototype Production | ✔✔ | ✘ |

| Mass Production | ✔ | ✔✔ |

Comparison of cold, hot and warm forming

| Hot Forming | Warm Forming | Cold Forming | |

|---|---|---|---|

| Characteristics | Forming with material heated above its recrystalization temperature. |

Forming done at temperatures between those for hot and cold forming. |

Forming done at/ near room temperature. |

| Forming Temperature |

1100°C ~1250°C (2012°F ~ 2282°F) |

300°C~850°C (572°F ~ 1562°F) |

Forming done at/near room temperature. |

| Required Loads | Low forming loads required | Medium loads required | Large loads required |

| Level of Precision | ✘ | ✔ | ✔✔ |

| Quality of Surface Finish |

✘ | ✔ | ✔✔ |

| Level of Geometry Complexity |

✔✔ | ✔ | ✘ |

| Ideal Production Quantity |

Best for mid-to-small scale production | Best for medium scale production | Best for large scale production |

| Pros / Cons | Because material is heated to above its recrystallization temperature, smaller loads are required to form material. Greater deformation is also possible allowing for very large or highly complex geometries. However, surface finish is often poor for steel products compared to warm and cold forming because surface oxidation and decarbonation occurs above 900℃(1652°F). The level of precision achieveable is also poor due to the expansion /contraction of metal as it is heated and cooled. | Warm forming aims to combine the strong points of hot and cold forming. It allows for better surface finishes than hot forming, but temperature control is difficult. More complex geometries are possible than with cold forming, but precision is not as high. | Because no heat is added to material, cold forming allows for high precision, high quality surface finishes, and high speed production. However, compared to hot forming the loads required to deform material are high and material deformability is low, thus requiring a high degree of manufacturing experience to achieve complex geometries. Tooling life varies by product, but it is common for tooling to last into the 10,000 parts range and higher. |

Screw

Threads

Grooves

Pointed tips

Rounded tips

Straight

Knurling

Diamond

Knurling

Spiral

Knurling

Leadscrews

Machined vs Rolled Threads

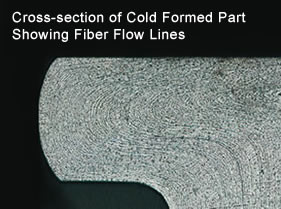

Rolled threads enable high-speed thread forming with no material lost as scrap and a stronger product overall because, unlike machined threads, the fiber flow lines of the material are left intact. Rolling also allows for lower costs and better turnaround time than machining.

Machined Threads

Cold Formed Threads

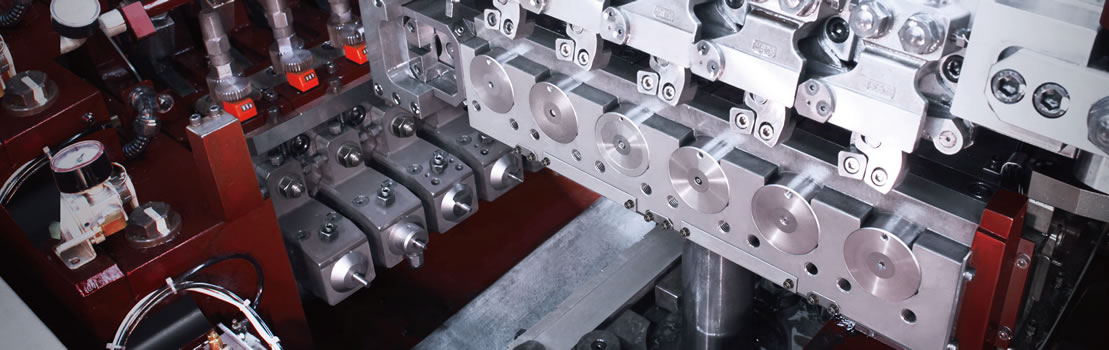

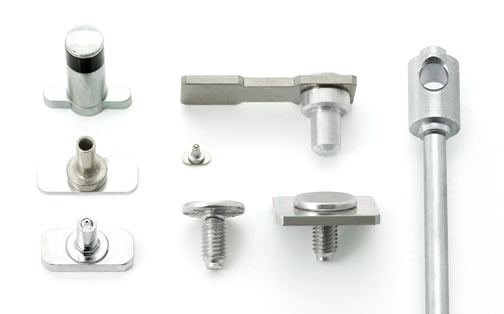

Custom Precision Forming

Precision forming for custom parts with shaft diameters up to 25mm (approx.1 in).

⇱ Enlarged View More >>Micro-Precision Forming

Precision forming for micro parts with shaft diameters 1mm (0.04in) or less.

⇱ Enlarged View More >>Deep Drawing

Deep drawing for parts with thin walls or deep holes that would otherwise be difficult to form from round wire material.

⇱ Enlarged View More >>Machining

Combining machining with cold forming to achieve high precision difficult with forming alone.

Rolling

From worm gears and knurling to unique rolled geometries.

Bending/ Flattening/ Trimming

A wide variety of secondary processes such as bending, flattening, and trimming.

Fastening/ Press fitting /Plastic Molding

Compound manufacturing that combines different materials through crimping, press fitting and/or plastic molding.

Processing Capabilities

Note: We are also able to perform tests to see if a material provided by the customer is forgeable.

Note: Please consult with us if your part is particularly long.

Note: What tolerances are possible depends greatly on part geometry and material.