Our Features

Our Features

Heading

Heading is a basic cold forming process. We have 1,200 formers and headers and produce 12 billion parts per year (8,000 different products).

Rolling

The rolling process imprints (rolls) various patterns onto cold formed blanks. It is also a cold forming process, so high speed production with little material loss is assured.

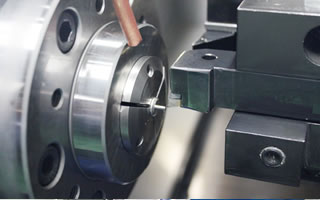

Secondary Fabrication

Fukui Byora employs a wide range of secondary processes, including machining, bending, pressing, fastening, and plastic molding.

Polishing and Cleaning

Cleaning is often done after heading and secondary fabrication to remove machine oil used during those processes. It requires a high level of expertise as cleaning procedures are tailored to the specific oil used, as well as the product’s shape and material.

Heat Treatment

With our vacuum furnaces and other heat treatment equipment, we ensure high quality heat treatment, including quenching, tempering, magnetic annealing, normalizing, and carburizing.

Surface Finish / Metal Plating

Our dedicated plating subsidiary allows us to provide suggestions and resolve technical problems quickly and reliably.

[ Tel ] +81 3-6228-4391

[ Fax ] +81 3-6228-4493

[ Business Hours ]

8am to 6pm (Japan Standard Time) Monday to Friday