Step 1. Your Inquiry

We utilize customer information on a given part to achieve maximum success.This information includes but is not limited to technical drawings of the part, quality specifications, and final application considerations.

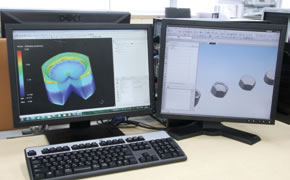

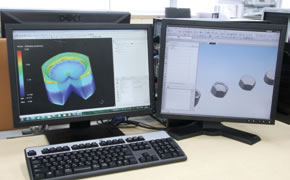

Step 2. Designing the Tooling and Manufacturing Process

Once we have your specifications, our engineers design a process to produce your parts using tools like FEM analysis to achieve the best solution possible.

Step 3. Determining Prototype Specifications

If necessary, one of our engineers will visit your site to discuss manufacturing details, tolerances, standards, etc that need to be decided with an initial prototype. After the details of the part drawing are decided, we will submit a quotation to you.

Step 4. Prototyping phase

During prototyping, dies are made and your part is produced. If there are issues with the prototyped part's dimensions, etc, die design is altered and more parts are made. This process is reiterated until the prototyped part meets your specifications.

Step 5. Evaluation and Approval

We will carefully examine the process capability and deliver the prototype to you along with a report of the results. Once you receive the prototype, you will be asked to check and evaluate it. We will also meet with you to determine the specifications for mass production (and provide a final quotation).

Step 6. Pre-Production and Mass Production

Once we obtain your approval, we will set up a production line based on the process layout designed at the mass-production planning stage and start mass production. We will start delivering mass-produced parts to you under initial production control guidelines.