Our Features

Our Features

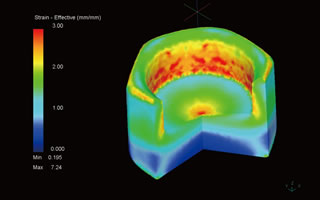

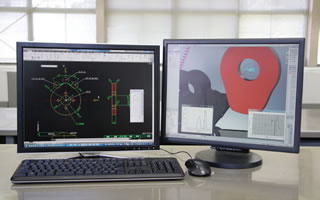

Optimal Process Design Based on FEM Analysis

We design the best possible manufacturing process for each part using FEM (finite element) analysis in combination with years of design experience.FEM analysis: An analytical technique frequently used to determine stress and strain in materials or machine components.

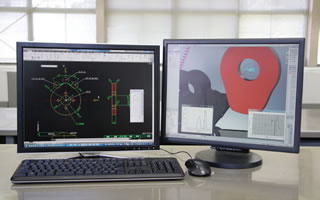

Developing Innovative Dies and Forming Machines

One of our strengths at Byora is our innovative design of tooling for each product and the design of the forming machines that we use. This innovativeness greatly expands what can be done with cold forming and provides our customers with the best product possible.

Quality and Accuracy Backed by Our Die-Making Expertise

In cold forming, the specifications of the die a part is made with, such as the die material, surface roughness, surface finish, and the way the die is made, significantly affect the quality of the final product. The die making/die design expertise that we have acquired through many years of manufacturing experience is a key factor behind the quality and precision of our products.

Basic Research and Technological Development

We strive to establish a foundation for continuous technological development and improve our technology through fundamental research in a wide range of fields related to cold forming, including materials, dies, lubricants, metal working equipment, and innovative manufacturing methods.

In-House Equipment Manufacturing Capabilities That Support Stable Production

Based on the need to manage what's going on on the shop floor, we have developed custom-made forming machines equipped with control systems that allow for stable, high precision production.

Rivet and Fastener Development and Research

As part of our development department, we have a dedicated fastener development team that is devoted solely to improving current standard fasteners and rivets was well to the development of new innovative fastening techniques.

Automotive

Various Products for Engines, Transmissions, Brakes, Safety Devices, Sensors, Electrical Components etc.

Medical

Various Products for Syringes, Guidewires, Endoscopes, Orthodontic Appliances, Artificial Legs etc.

Electronics

Various Products for Lights, LEDs, Batteries, Lead Terminals, Connectors, Relays, Electrical Contacts, Mechanical Components etc.

Construction / Architecture

Various Products for Housing Equipment, Fastening Products for Construction etc.

Other Applications

Various Products for Shoes, Bags, Glasses, Accessories, Gaming Devices, Office Supplies, Cooking Tools etc.

Contact Us

Contact us to ask about any of our products or services

by telephone or email.

[ Tel ] +81 3-6228-4391

[ Fax ] +81 3-6228-4493

[ Business Hours ]

8am to 6pm (Japan Standard Time)

Monday to Friday

[ Tel ] +81 3-6228-4391

[ Fax ] +81 3-6228-4493

[ Business Hours ]

8am to 6pm (Japan Standard Time) Monday to Friday