Contact Us

Contact Us

Frequently Asked Questions

Home >

Contact Us >

FAQ >

Technical

FAQ - Technical

Q1 .

What is the minimum lot size when mass-producing cold-formed parts?

A.

With cold forming, it is more cost effective to produce large quantities using the same die, so we recommend minimum orders of 10,000+ parts.

Q2 .

What is your production capacity?

A.

Depending on the size of part and the production machines used, we are capable of producing several hundred million parts per month. Depending on the machine used, we also have the option to build machines in-house to expand our capacity as needed. Please contact us for a production capacity estimate for your product.

Q3 .

What materials can you process?

A.

We can work with a wide range of metals, including pure iron, carbon steel, stainless steel, copper, brass, aluminum, titanium, Kovar, alloys, and other metals. We can also consider processing special materials provided by the customer. Please contact us to discuss your material requirements.

Q4 .

What material sizes can you work with?

A.

We have experience handling round wire material from 0.10 to 23mm in diameter. Depending on your desired part size, we may be able to modify our in-house equipment to meet your needs.

Q5 .

What lengths can you process?

A.

We have experience handling materials from under 1 mm to over 2m long. We can also offer special processing of long parts. Please contact us to discuss your requirements here.

Q6 .

What level of tolerance are you capable of with cold formed parts?

A.

It is possible to control dimensions down to the μm (0.0004in) range, but this depends greatly on the geometry and material of the part in question. Please contact us for questions regarding tolerances and precision.

Q7 .

Do you offer heat treatment?

A.

We handle many kinds of heat treatment in-house. For certain types, we utilize external contractors.

Types of Heat Treatment

Quenching and Tempering

Quenching is done to increase the hardness of metals. Although quenching increases hardness, it also makes the metal less tough and more brittle, so tempering is often performed after quenching to restore some of the material's toughness.

Annealing

Annealing softens the material and improves material ductility by removing some of the deformation caused by work hardening.

Normalizing

This heat treatment is performed to remove the internal deformation of a product caused during a forming process, to restore the metal structure to its normal state, or to make its crystal grains finer. It also enhances the strength and ductility of metals.

Carburizing

This heat treatment hardens the surface of material. The degree of hardening depends strongly on the amount of carbon, which means that only the surface of a product can be hardened while allowing its internal structure to remain soft. This technique is commonly used to provide products with both wear resistance and toughness properties.

Nitriding

This heat treatment exposes iron or a titanium alloy to a high-temperature nitrogen atmosphere to allow nitrogen to diffuse into the surface of the metal, thereby hardening the surface. The process causes little change in material dimensions and enables the manufacture of products with superior wear resistance.

Q8 .

Do you offer plating and surface treatment processes?

A.

Yes. We do much of our plating at our subsidiary, Wako Riken. For certain types of plating, we work with external plating companies. We provide zinc, copper, nickel, tin, gold, silver, rhodium, and chromium plating among others. Contact a sales representative for more information.

Types of Metal Plating

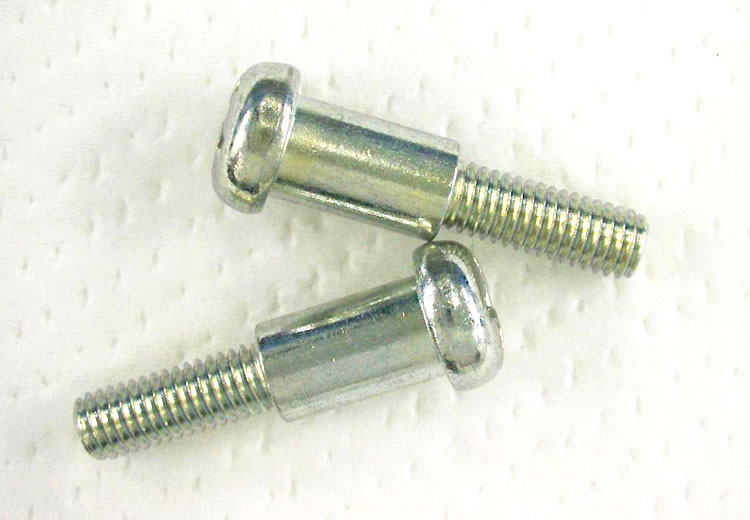

Zinc Plating

Iron and steel materials, which are prone to rusting, are commonly plated with zinc to protect against corrosion. After the plating process, the zinc plate is typically coated with chromate to further enhance the corrosion resistance. (Example: trivalent chromate plating)

Copper Plating

Copper plating provides excellent electrical conductivity and leveling and is extensively used as an underplate for electronic parts and decorative plating.

Nickel Plating

Nickel, which resists air and humidity much better than iron, is commonly used for anti-corrosion (anti-rust) and decorative applications.

Electroless Nickel Plating

Unlike nickel electroplating, this plating technique provides a uniform coating even on products with complex geometries.

Tin Plating

Tin plating, which provides a superior white luster and good solderability, is commonly applied to electronic parts.

Gold Plating

Gold plating provides low contact resistance as well as superior corrosion resistance, oxidation resistance, as well as excellent electrical and thermal conductivity.

Silver Plating

Silver plating, which provides superior electrical conductivity, is commonly applied to electrical contacts and connectors.

Rhodium Plating

Rhodium plating, which provides superior corrosion resistance, high reflectance, and a beautiful white luster, is commonly applied to accessories.

Chrome Plating

Chrome plating, which provides a beautiful metallic luster and superior corrosion resistance, is commonly used for decorative applications. It is also used for industrial applications, where its superior lubrication and anti-wear properties contribute significantly to reducing the costs of industrial products.

Other Types of Plating Provided

We also offer zinc-nickel plating (for corrosion resistance and thermal resistance), tin-cobalt plating (for discoloration resistance), and more.

Q9 .

Do you keep your standard products in stock?

A.

We keep our standard products in stock, but the amount in stock varies on a daily basis. Click here to contact us for more information.

Q10 .

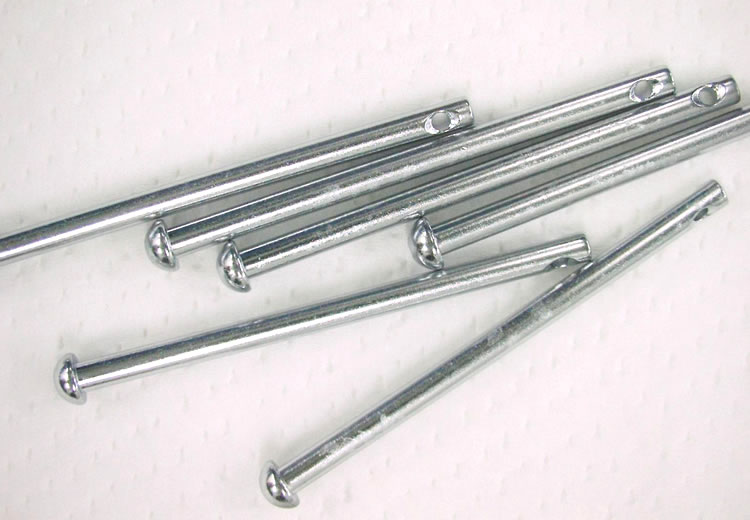

Can you provide information on selecting rivets / rivet sizes?

A.

Yes. Please feel free to contact us to discuss your application here.

Q11 .

Can you help us test fasteners to determine if Fukui Byora rivets will work for our application?

A.

Please contact us to discuss your specific application. Click here for more detailed information.

Q12 .

Can you design and build automatic riveting/fastening machines for fastening specific workpieces?

A.

Yes. Click here to contact us for more information.

Q13 .

Can you make custom rivet punches, jigs, or tools?

A.

We can, if you are planning to use them to fasten our products, including rivets and custom parts.

Contact us here.

Contact us here.

For our Fastening FAQ, click here

For our General FAQ, click here

Contact Us

Contact us to ask about any of our products or services by telephone or email.

[ Tel ] +81 3-6228-4391

[ Fax ] +81 3-6228-4493

[ Business Hours ]

8am to 6pm (Japan Standard Time) Monday to Friday

[ Tel ] +81 3-6228-4391

[ Fax ] +81 3-6228-4493

[ Business Hours ]

8am to 6pm (Japan Standard Time) Monday to Friday