▸ Products Menu

| Product Examples

| Products by Shape / Manufacturing Process

| Fasteners and Rivets

| FAQ |

Self-piercing Rivets

Home >

Products >

Fasteners and Rivets >

Self-piercing Rivets

Self-piercing Rivets Basics

No hole in workpieces needed

Self-piercing rivets punch through (pierce) through the workpiece as they fasten them together, thus eliminating the need for pre-made holes in the workpiece.

Secure fastening of dissimilar materials

Self-piercing rivets can be used to fasten dissimilar materials that are difficult to weld together like aluminum and steel, or even metal and wood.

Perfect for fastening painted/coated steel plates

Self-piercing rivets fasten workpieces without heating the material, thus eliminating the need for repainting painted workpieces.

Clean fastening for a cleaner workplace

No sparks, smoke or swarf is generated when fastening Self-piercing rivets, all of which contributes to a cleaner workplace overall.

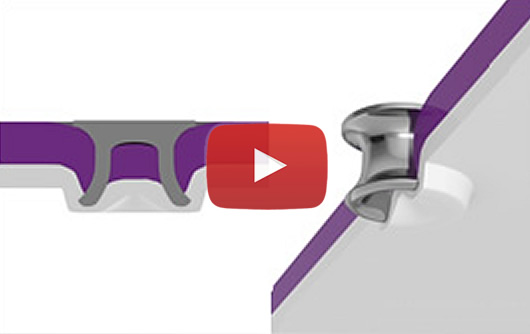

Fastening with Self-piercing Rivets

Comparison Graph: Fastening Strength of Self-piercing Rivets vs. Other Fastening Techniques

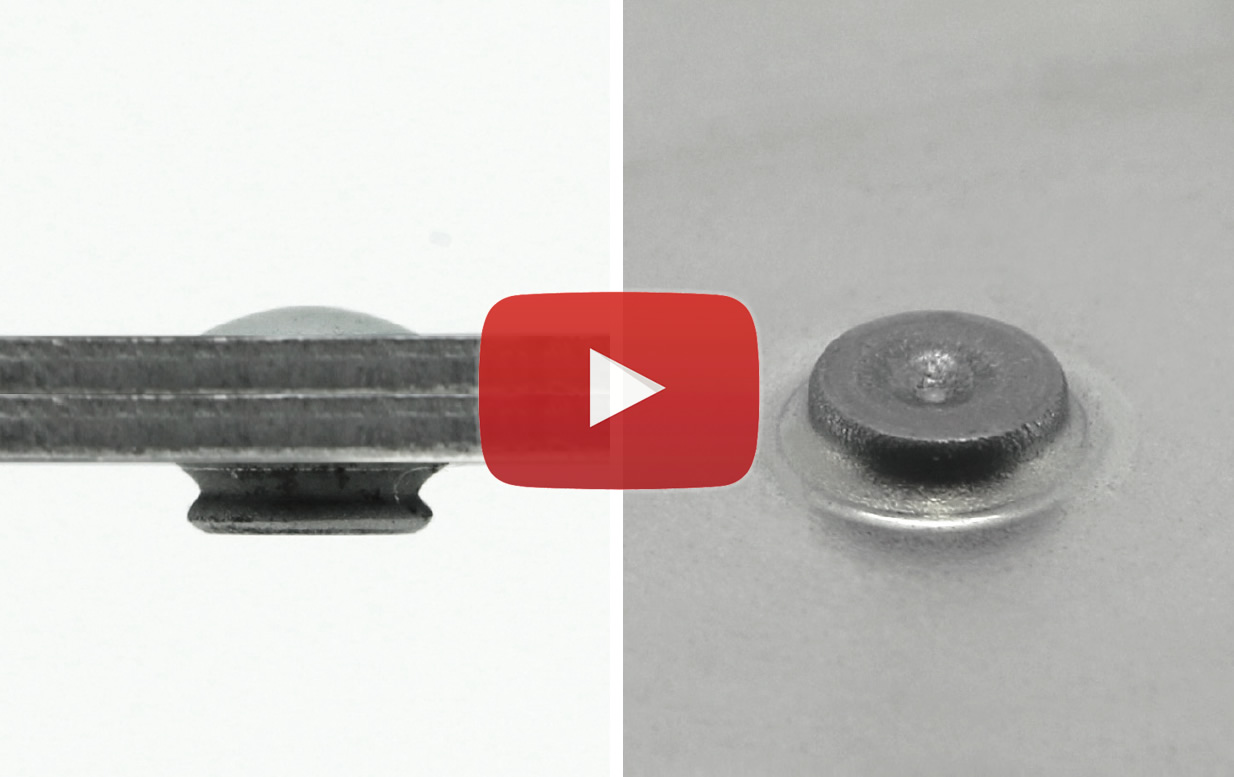

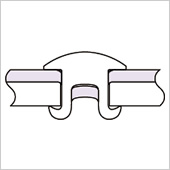

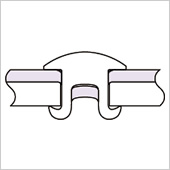

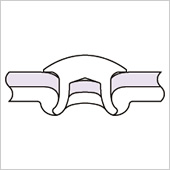

Standard Self-piercing Rivet

Self-piercing rivet

The basic self-piercing rivet. Self-piercing rivets pierce through workpieces while fastening them together. No pre-made hole in the workpiece(s) is required before fastening.

Examples of Customized Self-piercing Rivets

Sealed self-piercing rivet

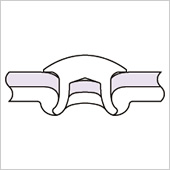

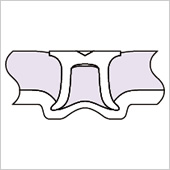

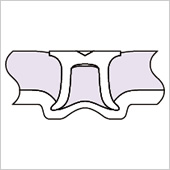

Three-legged rivet

The three-legged design prevents formation of swarf during fastening and helps prevent rotation between workpieces.

[ Uses ]

Noise barriers, automotive, and construction applications

Noise barriers, automotive, and construction applications

Self-piercing bolt

Self-piercing bolts are used to replace welded-on bolts in some applications. They eliminate the need for a pre-drilled hole and touch-up work as well as keep the joint area clean.

[ Uses ]

Motor attachment bolts

Motor attachment bolts

Half piercing rivet

By making a pre-drilled hole in the thicker workpiece, the half-piercing rivet can fasten thicker workpieces than other self-piercing rivets.

[ Uses ]

By making a pre-drilled hole in the thicker workpiece, the half-piercing rivet can fasten thicker workpieces than other self-piercing rivets.

By making a pre-drilled hole in the thicker workpiece, the half-piercing rivet can fasten thicker workpieces than other self-piercing rivets.

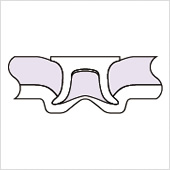

Low-profile rivet

The smooth edges around the shank hole of the low-profile rivet make for smoother curl side (exit side) joints after fastening reducing the chances of the joint interfering with other components in the final application.

[ Uses ]

Shutter rails (sliding part) and signboards

Shutter rails (sliding part) and signboards

Rivet for plywood / plaster

Using self-piercing rivets eliminates the need for drilling holes in plywood and drywall and contributes to a cleaner work environment.

[ Uses ]

Shipping containers (Fastening plywood to steel plates) and building components

Shipping containers (Fastening plywood to steel plates) and building components

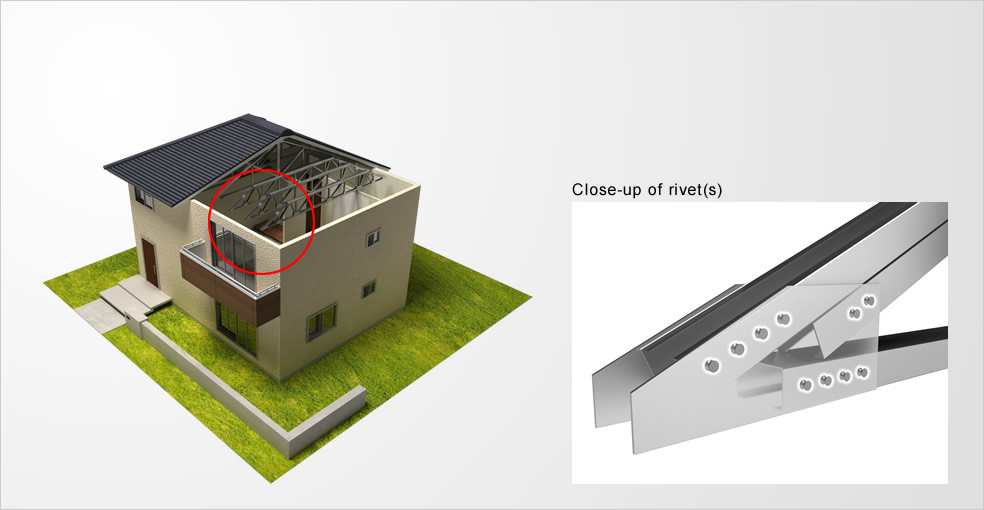

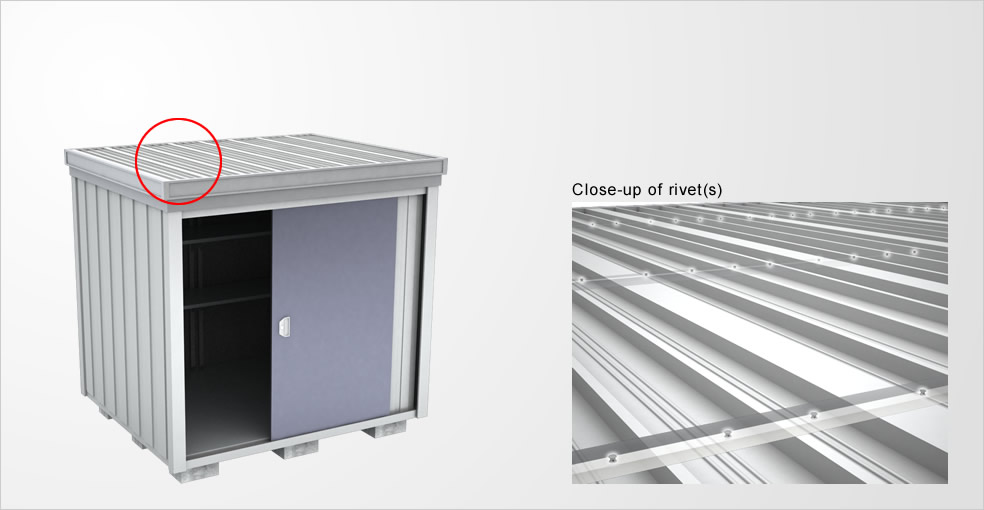

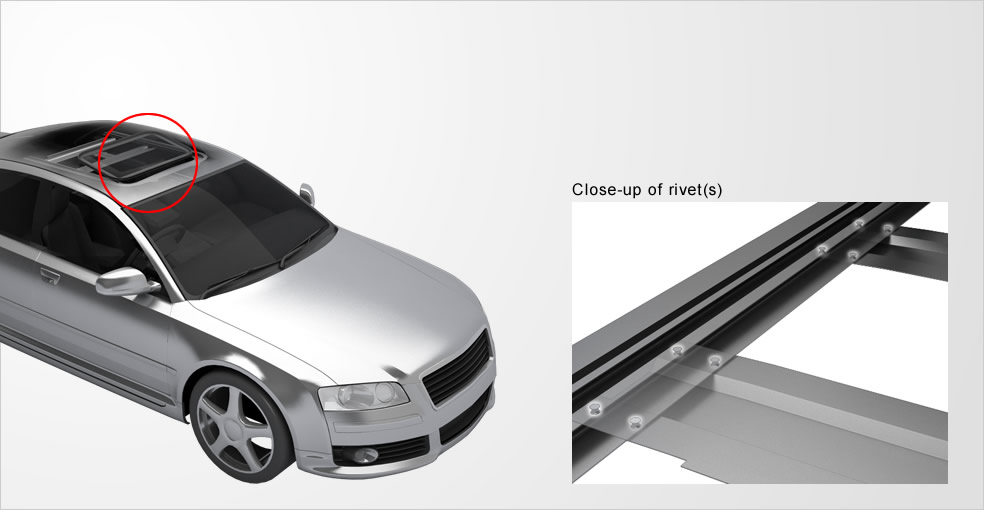

Example Applications for Self-piercing Rivets

PDF DOWNLOAD